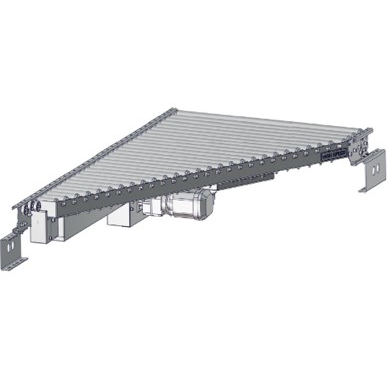

Product Introduction: Driven Roller Junction Conveyor

Product Overview

The Driven Roller Junction Conveyor is a high-performance material handling system designed to efficiently merge or divert items from one conveyor line to another, ensuring seamless material flow in multi-directional conveyor systems. Featuring powered rollers, this system enables smooth transitions between conveyor lines, eliminating the need for manual intervention. It is particularly suitable for high-speed sorting, packaging, and distribution applications in logistics, manufacturing, and e-commerce industries.

Product Features

- Efficient Merging and Diverting

Enables smooth and precise merging or diverting of materials from multiple conveyor lines into a single line or vice versa, improving overall system efficiency. - Powered Rollers for Smooth Flow

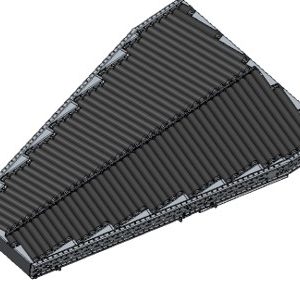

The driven rollers provide consistent movement of materials, ensuring minimal friction and preventing material jams, even at higher speeds. - Customizable Configuration

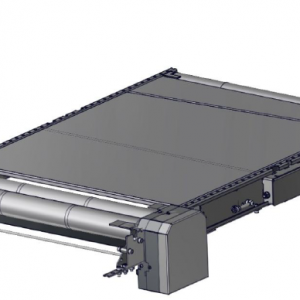

Available in a variety of layouts, including different angles, roller spacing, belt widths, and speeds to meet specific material handling requirements. - Durable and Reliable

Built with high-quality materials, the system is designed to withstand continuous use in demanding environments, offering long-lasting and dependable performance. - Minimal Maintenance

Designed for low maintenance, the Driven Roller Junction Conveyor is built with robust components that reduce downtime and service costs. - Versatile Applications

Suitable for handling a wide range of materials, including cartons, totes, and heavy packages, making it a versatile solution for various industries.

Technical Specifications

- Number of Rollers: 2–6 (customizable)

- Conveyor Angle: 0° / 30° / 45° / 90° (customizable)

- Roller Diameter: 50mm – 89mm

- Conveyor Length: 1m – 15m (customizable)

- Conveyor Speed: 0.3 – 2.5m/s (adjustable)

- Load Capacity: Up to 300 kg/m²

- Frame Material: Stainless steel, powder-coated steel, or aluminum

Applications

- Logistics and Distribution: Perfect for sorting and merging packages, parcels, and products in high-speed sorting centers.

- E-commerce: Enhances operational efficiency by enabling precise diverting and merging of goods during order fulfillment processes.

- Manufacturing: Ideal for assembly lines requiring smooth material transitions and consistent flow of parts or products.

Our Advantage

JK Conveyor Systems specializes in delivering high-quality Driven Roller Junction Conveyors that help streamline material handling processes across various industries. Our tailored solutions are designed to improve operational efficiency, reduce downtime, and enhance overall system performance. With a focus on durability and customer satisfaction, we provide reliable and cost-effective solutions that meet your unique needs.

Contact us today to discuss how our Driven Roller Junction Conveyor can optimize your material handling system!